New uses for steel slag

Experts say a by-product of steel making can be used to both treat wastewater and make stronger concrete.

Experts say a by-product of steel making can be used to both treat wastewater and make stronger concrete.

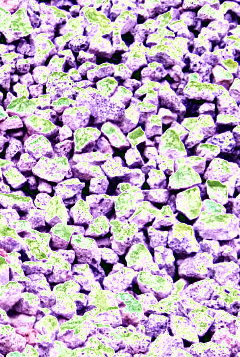

Steel slag is produced during the separation of molten steel from impurities, and is often used as a substitute aggregate material for making concrete.

It can also be used to absorb contaminants like phosphate, magnesium, iron, calcium, silica and aluminium in the wastewater treatment process, but loses its effectiveness over time.

Engineering researchers have examined whether slag that had been used to treat wastewater could then be recycled as an aggregate material for concrete.

They found that concrete made with post-treatment steel slag was about 17 per cent stronger than concrete made with conventional aggregates, and 8 per cent stronger than raw steel slag.

It appears that the chemical properties of the slag are enhanced through the wastewater treatment, so it performed better when used in concrete. Essentially, the things that purifiers remove from water are actually beneficial when it comes to concrete, creating a perfect match.

“The global steel making industry produces over 130 million tons of steel slag every year,” water engineer Dr Biplob Pramanik said.

“A lot of this by-product already goes into concrete, but we’re missing the opportunity to wring out the full benefits of this material.

“Making stronger concrete could be as simple as enhancing the steel slag by first using it to treat our wastewater.

“While there are technical challenges to overcome, we hope this research moves us one step closer to the ultimate goal of an integrated, no-waste approach to all our raw materials and by-products.”

Print

Print